- How to Design an Ergonomic Operator Cab

- Consider Operator Comfort

- Fabricate Operator Cab Solutions With Superior Manufacturing Company

An efficiently designed machinery operator cab can make a big difference in how the operators perform during a shift and how they feel afterward. Tailoring your cab designs to create a more ergonomic environment ensures that your operators have the most effective workspace possible. There are numerous factors that can affect the ergonomics of an operator cab, including the seat position and back support. Find out what factors you should consider when designing the optimal operator cab environment.

How to Design an Ergonomic Operator Cab

Designing the operator cabs for your equipment gives you the opportunity to account for specific design elements that can help increase the comfort of the cab. An ergonomic design keeps the operator’s comfort a top priority so they can work efficiently. Because each cab and each operator have different sizes and preferences, making several components of the cab adjustable is important for optimal comfort and productivity. Consider how making these aspects of the cab adjustable can help create an ergonomic cab:

- Seat height: Your cabs need to accommodate operators of varying heights. To accomplish this, include a seat with adjustable heights. An adjustable seat height allows all operators to sit at an appropriate level for maximum visibility of the floor in front of and around the machine.

- Armrests: Whether the armrests in the cab are simply for support or house a majority of the machine controls, the armrests themselves should be adjustable. Adjustable armrests allow the operator to sit comfortably in the seat without straining themselves to reach the controls.

- Seat position: Adjusting the seat’s position in the cab is beneficial because it allows the operator to swivel in place and lean backward. With these features, the operator can relax in the seat during downtime and easily turn to the sides for more visibility.

- Reach for pedals: Similar to adjusting the seat’s height, the seat should also slide forward and backward so all users can comfortably reach and use the pedals on the floor. The operator should be able to sit comfortably in the seat while still reaching the pedals.

Adjustable features in the operator cabs will help to improve the operator’s experience, thus helping them be more efficient and productive.

Consider Operator Comfort

Studies have found that 100% of operators spending their shifts in machinery cabins suffer from some level of back, neck, leg, arm or shoulder pain. In many cases, this pain reaches high levels within just three hours of continuous work. The quick onset of pain and discomfort is often due to minimal comfort features in operator cabs. When planning your operator cabin design, be sure to consider how these features can improve the performance of enclosed cabs

Vibration Felt Through the Floor and Controls

To create more comfortable operator environments, ensure the vibrations from the machinery can’t be felt through the floor, seat or controls. According to the CDC, this is an important guideline in machine cab design, and in over half of the machinery studied, operators felt vibrations through the floor and controls. After continuous exposure, vibrations absorbed through the hands and feet can lead to musculoskeletal disorders like Hand-Arm Vibration Syndrome (HAVS).

More mildly, vibrations cause fatigue and discomfort, which will impact the operator’s performance.

The Temperature in the Cab

Much like the temperature of a classroom or office, the temperature in a cab can affect the operator’s productivity and comfort. Temperature controls help create a more comfortable environment to work in. When workers are able to adjust the temperature to meet their preferences, they’ll stay comfortable whether it’s hot or cold outside the cab.

Back and Lumbar Support

Heavy equipment operators are typically seated for the majority of their shift, often without getting up for hours at a time. Without the right back support, this can have detrimental effects on posture and back condition. A seat with proper lumbar and back support helps operators maintain proper posture and supports the lower back during long hours in the seat. Back support is crucial for helping to minimize back pain and create an ergonomic cab design.

Design Efficient Placement for Controls

Another aspect of operator cab design to keep in mind is the placement of controls. The position of cab controls can have a significant impact on the ergonomics of the cab as a whole. When primary controls are out of immediate reach, the operator is forced to stretch, lean or sit in unnatural positions for long periods of time to use that control. Many cabs have controls on the armrests for easy access, though it’s critical that all the primary controls go on the armrests.

With an ergonomic control placement, operators can avoid straining themselves to reach the primary controls. With primary controls assembled on the armrests, other operations like temperature control and other less frequently used controls can go on additional stands or displays. Keeping the primary controls of the machine on the armrest assembly can also boost productivity, as their location will be much more convenient and easy to use.

Additional Space for Extra Gear

When considering ergonomics for operator cabin design, it’s helpful to think of the cabin as the operator’s office. While many employees have lockers or offices to keep their belongings in, machinery operators often lack storage for their extra gear and personal belongings. When designing your cabs, it can be helpful to incorporate additional space for operators to keep their gear, extra clothing layers, keys, wallet and more. For example, the control panel on the armrest could lift up to uncover a compartment built into the seat.

Providing additional space keeps coats, drinks, paperwork and more out of the way and in a safe place rather than covering controls or laying on the floor.

Fabricate Operator Cab Solutions With Superior Manufacturing Company

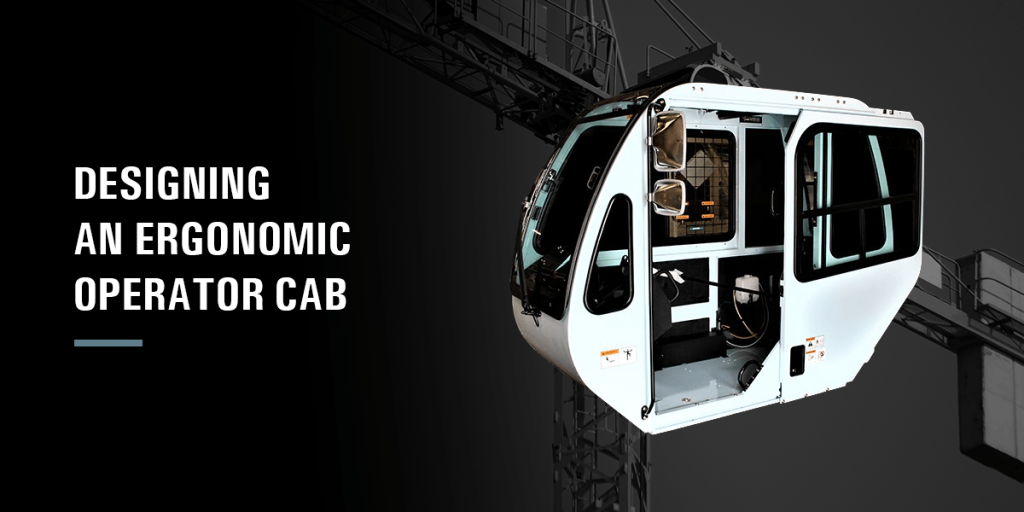

The design of your operator cabs can make all the difference in your employee’s efficiency, comfort and overall productivity. When we design and build cabs for heavy machinery, we prioritize comfort, safety and productivity. With over 35 years of cab manufacturing experience and more than 75 years of industry experience, our team at Superior Manufacturing specializes in a variety of cabs for machinery ranging from cranes to highway equipment.

We’ll work with you to create operator cab designs that fit your needs and offer benefits like reduced noise and vibration, temperature control and 360-degree visibility. Our experienced team will assist you from design to assembly and will deliver your finished products as soon as needed. To request a quote and find out how we can create solutions for you, contact our team or browse our products online.